Lightweight, Cost-Effective, Fast: There Are 5 Interesting Facts about the uLite Complex

UST Inc. has repeatedly talked about the advantages of the uLite transport and infrastructure complex. Today we focus on the interesting facts about the company's first project to apply in the business sector. How light is the uLite design compared to other uST complexes? What can be used to demonstrate its outstanding energy efficiency? How much faster is it than alternative versions? The answers to these and other questions are provided below in our article.

Fact 1. Incredibly Lightweight Design

In the uLite complex are used some of the lightest structures from the previously implemented uST versions. The weight of the metal of one intermediate support is just 2 tons. For comparison: the total weight of the support of the semi-flexible heavy-load string rail overpass in the EcoTechnoPark is more than 19 tons. That is to say, the supports of the uLite complex are almost 10 times lighter.

Fact 2. It is 3 Times Faster Than a Gondola Lift

uLite has a particular advantage in the speed of ride. uPod is more than 3 times faster than a cable-car or a gondola-type lift. At the same time, the operation of an electric rail vehicle is incomparably more cost-effective.

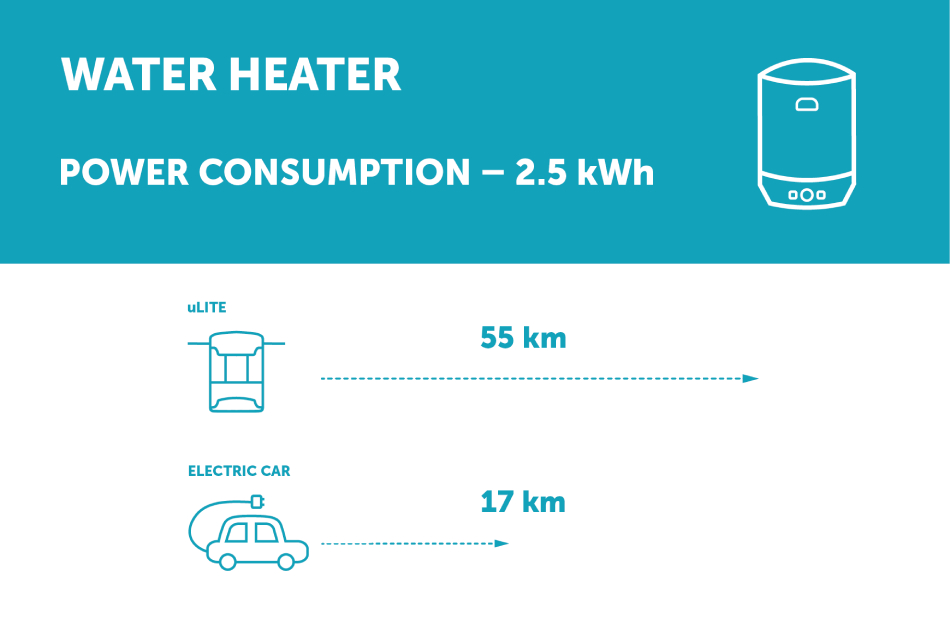

Fact 3. One Hour of Operation of the Boiler is Equivalent to 55 km Distance Covered by uPod

UST Inc. specialists compared the energy efficiency of uLite by comparing the indicators with the energy consumption of the boiler. The power of an electric water heater with a volume of 50 liters is about 2.5 kWh. The energy that the boiler will consume in an hour of operation will be enough for uLite to drive 55 km. For reference, a conventional electric car will travel about 17 km.

Fact 4. Full Automation

uPod rides on call: to start driving, the user should press a button at the station or in the cabin of uLite. Using the remote control stand, one can contact the dispatcher. The two-way communication system in uPod ensures the contact between the transport facility and the control room throughout the entire route.

Fact 5. The Rail Body Is Made of Aluminum

For the first time, an aluminum rail body was used in the design of the track structure. Aluminum has a lower weight compared to steel, ensuring the route lightness. The unique shape of the rail body, developed by UST Inc. specialists, was made by the drawings of the Russian company using metal extrusion.

More news

News

10 May 2023

Improved uFlash is Ready for Testing

High-speed uFlash is installed on the track structure in EcoTechnoPark. After the upgrade, uFlash will have to undergo series of research tests that will follow the commissioning works.

News

9 Junе 2022

International Arctic Summit: UST Inc. Presented a Solution for the Development of the Far North Territories

From June 8 to 10, the 6th International Arctic Summit “The Arctic: Prospects, Innovations and Development of Regions” is being held in Moscow and St. Petersburg. Unitsky String Technologies Inc. along with the other organizations of Unitsky Group of Companies takes part in this large-scale forum.

Opinion

31 January 2022

Unitsky String Technologies Inc. Took the Stage in Agenzia Italia

The publication mentions that Unitsky String Technologies Inc. suggests passenger and cargo transportation, which could bridge the dessert in the UAE at record-breaking speeds.